COLATAN CF2

Physical property:

Appearance: reddish powder

PH value:6.5-6.8

Moisture content:max.9%

Chemical feature

COLATAN CF2 is a water resistance natural starch addtive, a chemically modified tannin of polyphenol chemical structure( flavonoid) obtained from extracted substances of the Colorado Quebracho(Schinopsis Lorenzii) arboreal species that grows in the Northeast of Argentina..COLATAN CF2 is specifically developed to be used as a natural starch additive to provide high water resistance properties when applied to corrugated cardboard, to give good bonding especially for high speed corrugator.Being the universal natural starch addtive for the cardboard industry, it can be added without changing your own formula , nevertheless, it could offer adhesive with both high bonding and good water resistance. Besides,CF2 is an additive to improve the green bond, it means that the additive helps to take the water out from the adhesive while it is running on the machine.

Scientifically talking, the water has a very important role in the adhesive:

1-water is the carrier to transport the raw satarch from the kitchen or the storage tanks to the papers

2-water is needed to produce the gelatinization process of the raw starch

3-water helps to wet the papers and so, helps the adhesive to penetrate into the papers

Once the glue is on the papers some effects occurs like:

1- water wet the papers

2-adhesive penetrate into the papers

3-the papers goes into the hot plates where some others effects ocurs on the adhesive

a)adhesive increase its temperature

b)adhesive increase its viscosity dramatically because the raw starch start to gel

c) as much time the papers are into the hot plates, more raw starch become in gel, till all raw starch is already gel, in this point many water molecules are between gel satrch molecules, but to get a dry cardboard or hard cardboard, is needed to take out most of this water.

d)Finally, to take these water molecules out, is needed to use some energy from the hot plates just to take out the water from the starch molecules and by this way these water molecules are free to evaporate from the cardboards.

e)How CF2 works

As CF 2 has much more affinity for the gel starch molecules than the water molecules, so, CF2 goes between gel starch molecules leaving the water molecules free just to evaporate. As you can see, using CF 2 is not needed an extra hot in the hot plates and for this reason the extra hot can be used just to evaporate water, (not to take the water out from the starch molecules), and this is the reason the machine can run faster.

Anyhow, CF2 could offer adhesive with its super bonding and fast drying properties, which as a result,leading to a perfect machine speed enhancing and tremendous application decrease.

ADVANTAGES

As a natural tannin product, CF2 has good natural tacky which will not affect the final adhesive but on the contrary, increase its bonding capability. It could run the machine 15-20% faster then before. Base on CF2’s high bonding capacity, allows machine to run at lower application: since they are almost 80% of water in the glue applied to the paper, and more water means more soft cardboard, therefore, by reducing the application, mean less glue on the paper, you can get higher hardness and tensile strength in the final board as CF2 could enable the machine to reduce at least 30-50% application.

Eco-friendly WATERPROOF CARDBOARD=Tannin acid+formaldehyde

Colatan CF2 by reacting with formaldehyde can produce the waterproof cardboard( the glue waterproof),to make cardboard in compliance with FEFCO n°9 test and LINK test and etc. waterproof standards, the test result is: for high grammage paper cardboard is 24 hours without delaminating in general , but it various between 10-24 hrs depends on different type of cardboard.While cardboard without CF2+formaldehyde, will delaminate in very short time when going through above tests! Since CF2 contains tannin acid of polyphenol structure(flavonoid) that can react fully with formaldehyde(HCHO) to exhaust completely the formaldehyde that added into the adhesive, thus making final cardboard ZERO formaldehyde and any kind of its drivatives and precursor .Therefore,with COLATAN CF2 can be obtained corrugated cardboard with excellent resistance to moisture, especially for boxes ,going to be subjected to extreme conditions of high humidity, as in the case of cold rooms, it will offer box with excellent compression strength.

In a word, Colatan CF2 as a natural water resistance additive extracted from Quebracho tree, its presence in Chinese market has been perfectly filling the vacancy of natural additive in Chinese market.

Standard formula for reference

Parameters of the glue with CF2:

1.Gel point:60-63℃

2.Viscosity: S/F 15-20S, D/B 20-25S ( measure by LOVE CUP), normally, we prefer to adopt the present viscosity of your own glue.

3.Solid contend: around 20%

4.Formula: just replace our additive with which you are using now.

|

1.Two tanks system |

|

|

Primary tank |

|

|

Water |

171 kg |

|

Corn starch |

23 kg |

|

caustic |

6,5 kg (solid) |

|

Heat |

60 °C |

|

Stir time |

15minutes |

|

Secondary tank |

|

|

Water |

557 kg |

|

Corn starch |

233 kg |

|

CF2 |

5 kg |

|

Stir time |

10 minutes |

|

Drop down the primary tank into the secondary tank in 10 minutes, |

|

|

Borax |

4kg |

|

stir 10 to 15 minutes |

|

|

2.One Tank system |

|

|

Water |

880 lts |

|

Caustic |

4 kg |

|

Starch |

250 kg |

|

Caustic |

4 kg Predisolve in 10 kg of water |

|

Stir untill the viscosity is OK |

|

|

CF 2 |

5 kg |

|

Borax |

4 kg |

|

Stir 10 to 15 minutes |

|

|

Note: pre-dissolve CF2 with 70℃ hot water, if you have the electronic stirrer, it can be disolve with water of normal temperature |

|

|

3.High share system |

|

|

Water |

273 kg |

|

Corn starch |

20 kg |

|

Caustic 50% |

16 kg |

|

Borax(deca) |

0,6 kg |

|

Stir time |

30 sec |

|

Heat |

40 °C |

|

Stir time |

3 minutes |

|

Water |

409 kg |

|

CF2 |

5 kg pre-dissolve CF2 with 10kg of water |

|

Corn starch |

271 kg |

|

Borax(deca) |

2 kg |

|

Stir time |

30 sec |

Important points:

1.To produce high waterproof cardboard, we recommended dosage of formaldehyde to be 10% of the weight of CF2( but if CF2 is lower than 10 kg, the formaldehyde shall always be 1 kg), then stir 5 minutes.

2.Colatan CF2 is compatible with any of the adhesive, no specail facilities or treatment is required and can be used the same as other additives.

3.due to CF2 can fasten the drying of the adhesive, therefore, it is important to increase the machine speed to avoid the glue from being over cooked or a fragile cardboard.

4.cardboard store after24 hrs can get the best physical performance like edge/flat crush tests, etc.

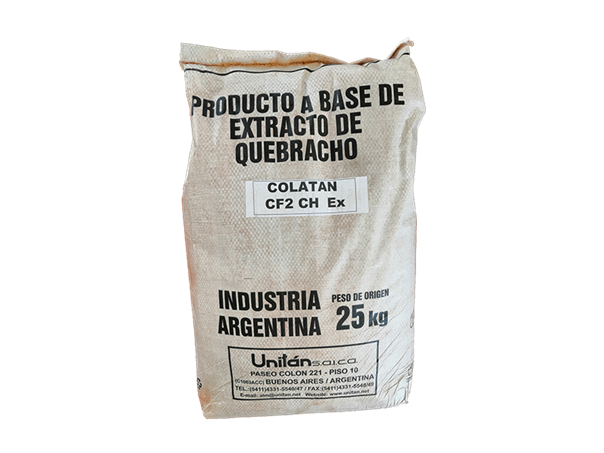

Package

Net weight:25kg/bag, 1125kg per pallet.